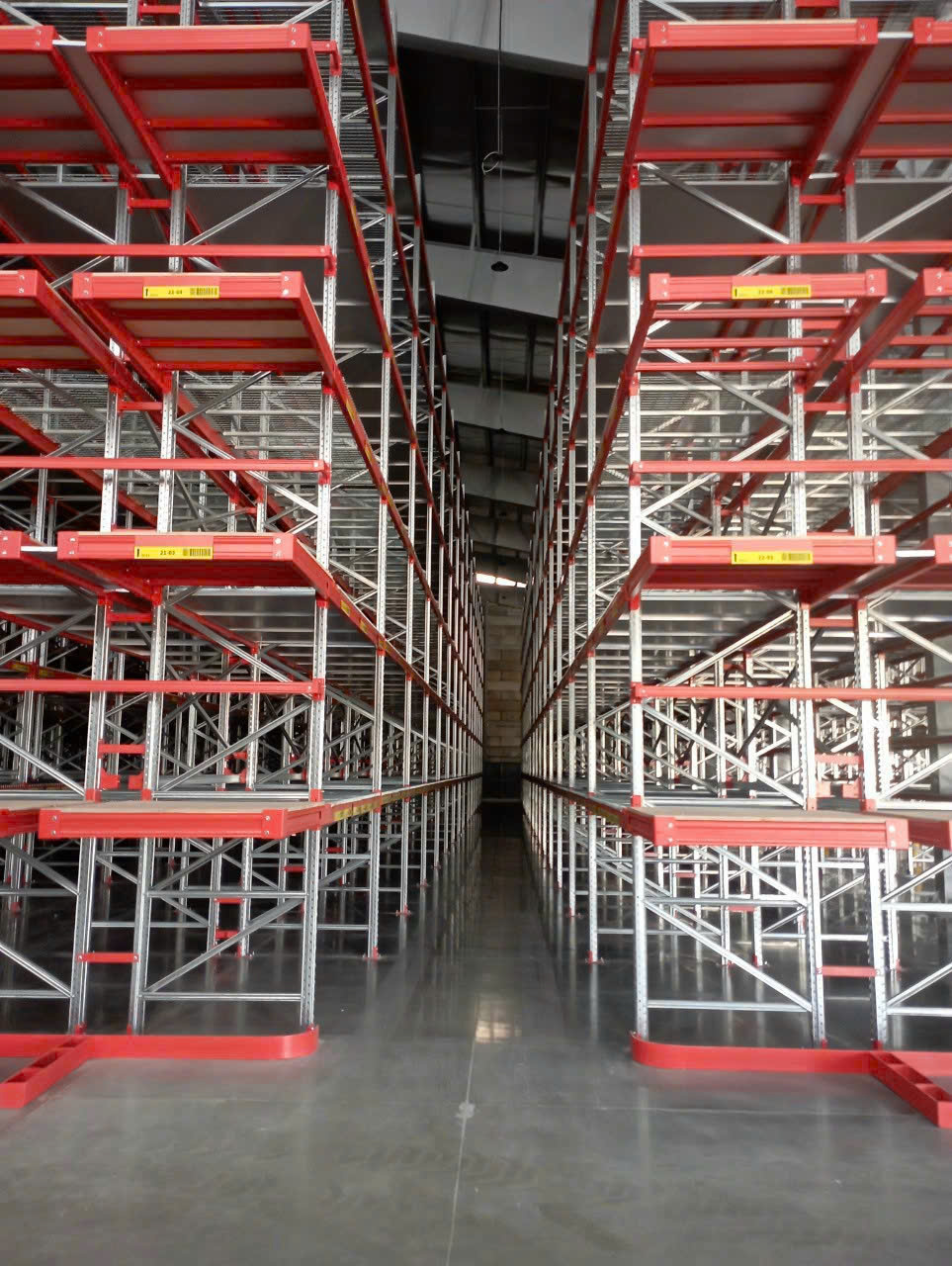

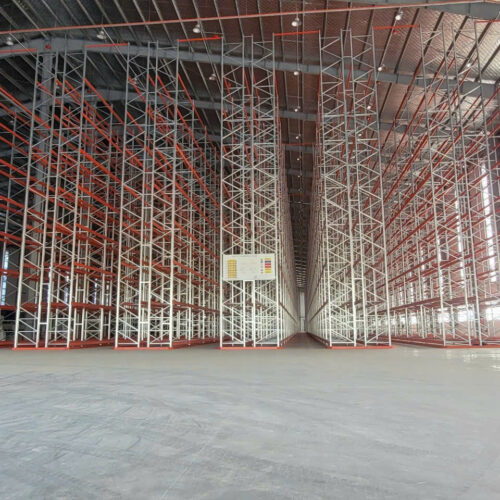

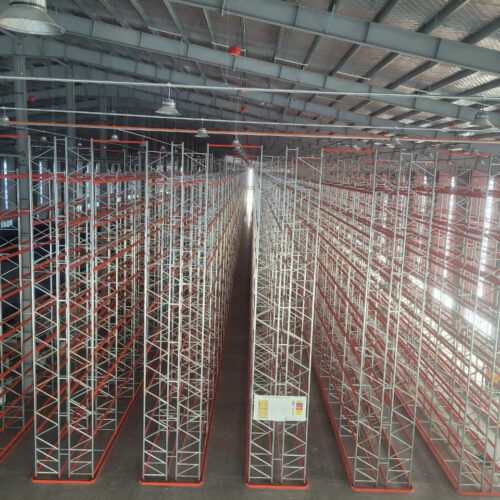

In the context of continuously rising land and warehouse rental costs, maximizing storage capacity per square meter has become the top priority for logistics and manufacturing businesses. TÍN ĐẠT’s Very Narrow Aisle (VNA) racking system is an advanced and groundbreaking solution, specifically designed to address this challenge effectively. As a leading manufacturer with extensive experience and modern technology, we are confident in delivering durable, safe, and efficient VNA racking systems that help your business fully unlock the potential of your warehouse.

What is a Very Narrow Aisle (VNA) Racking System? Understanding the Advanced Storage Technology

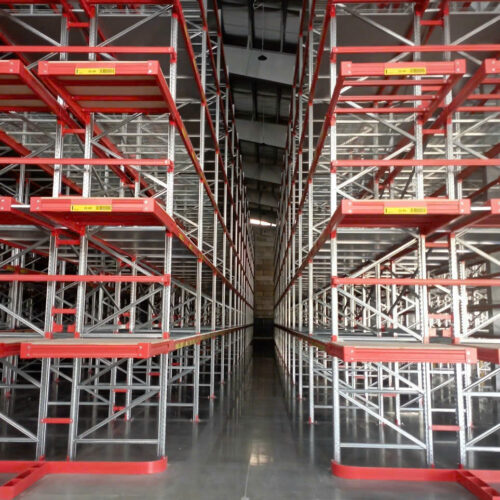

VNA racking is an upgraded version of the Selective racking system, designed with extremely narrow aisles between racking rows—only about 1.5m–1.8m compared to the 3m–4m aisles of conventional Selective racks. This reduced aisle width significantly increases storage density while still allowing 100% access to each individual pallet. To operate efficiently in such spaces, the VNA system requires specialized forklifts (VNA trucks) capable of maneuvering and lifting in tight spaces.

The basic components of TÍN ĐẠT’s VNA racking system include:

-

Upright frames: Made from high-strength roll-formed steel, providing excellent rigidity and high load capacity for the entire system.

-

Beams: Horizontal members that form the storage levels where pallets are placed. Beams can be easily adjusted to fit various pallet sizes.

-

Bracing: Includes horizontal and diagonal bracing to enhance rigidity and stability, especially important for the taller structures typical of VNA systems.

-

Guidance rails: Essential components that help VNA forklifts move precisely and safely within narrow aisles, preventing collisions with the racking structure.

-

Flooring and protective accessories: Ensure safety for goods and personnel, including anti-fall mesh, column guards, and other safety devices.

Outstanding Advantages of TÍN ĐẠT’s Very Narrow Aisle (VNA) Racking

With a manufacturing process compliant with strict international technical standards such as FEM 10.2.02 and AS4084-2012, TÍN ĐẠT guarantees top economic and operational benefits:

-

Maximized storage density: The most notable advantage. VNA racking can increase storage density by 40–50% compared to Selective racking, making optimal use of both floor space and warehouse height.

-

100% pallet access: Despite narrow aisles, the system still allows direct access to every pallet, enabling accurate and flexible inventory management under either FIFO (First In, First Out) or LIFO (Last In, First Out) principles.

-

Optimized operational efficiency: With guidance rails and specialized forklifts, goods handling is faster, more accurate, and requires less travel time, thus improving productivity.

-

Flexible design: TÍN ĐẠT can customize the dimensions, height, and configuration of the VNA system to match your pallet types, ceiling height, and load capacity requirements.

-

High durability and safety: Manufactured from high-strength steel, with surfaces treated by powder coating or galvanization for excellent environmental resistance, capable of heavy load capacities (up to 2000kg/pallet), ensuring total peace of mind for your business.

-

Suitable for various industries: Ideal for businesses with a large number of SKUs requiring precise inventory management and space optimization, such as pharmaceuticals, electronics, food storage, and third-party logistics (3PL).

Considerations When Implementing a Very Narrow Aisle (VNA) System

While offering outstanding density efficiency, deploying VNA racking requires careful consideration of:

-

Investment in specialized forklifts: Requires VNA forklifts or Combi/Turret trucks with the ability to rotate forks 180 degrees and operate within narrow aisles. These typically have a higher cost than conventional forklifts.

-

High installation precision: The VNA system demands absolute accuracy in installation and alignment of guidance rails to ensure smooth and safe forklift operations.

-

Flat warehouse floors: To operate efficiently and safely, VNA forklifts require highly level flooring.

-

Not ideal for extremely high throughput per aisle: Although efficient, very high and continuous throughput in a single aisle can cause bottlenecks, as typically only one forklift operates in an aisle at a time.

TÍN ĐẠT – Your Leading Expert in Very Narrow Aisle (VNA) Solutions

At TÍN ĐẠT, we are not only a manufacturer but also a strategic partner in optimizing your supply chain. With an experienced team of engineers and specialists, we offer a complete service package including:

-

In-depth consultation and design: On-site warehouse surveys, analysis of goods flow, and optimal VNA system design tailored to your business needs and operations.

-

Superior manufacturing quality: Advanced technology, automated welding lines, and strict quality control processes to meet international standards.

-

Professional and precise installation: Skilled technicians trained specifically for VNA systems, ensuring fast, safe, and highly accurate installation.

-

Dedicated after-sales service: Long-term support to maintain smooth and efficient system operation throughout its lifecycle.

Contact TÍN ĐẠT today to boost your warehouse efficiency!

If your business is looking for a breakthrough storage solution to maximize space and enhance warehouse operations, TÍN ĐẠT’s Very Narrow Aisle (VNA) racking system is the optimal choice.

CÔNG TY CỔ PHẦN THIẾT BỊ CÔNG NGHIỆP TÍN ĐẠT

Hotline: [0909957491]

Email: [thanhhung@giakechuahang.com]

Website: [Trang Chủ – GIÁ KỆ CHỨA HÀNG TÍN ĐẠT]

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.